To feel a cooling breeze when it is very hot is a real relief and joy. We rely on the cooling breeze of a neck fan when walking on the beach, and we use mister fans on the patio or when camping. When the air conditioner in the office does not cool the air enough, a small desk fan helps us cool down and work with concentration.

In antiquity, people idolized the wind and the other elements—water, earth, and fire—and, over time, learned to control them. Unofficially, in ancient times, people used palm leaves to create a refreshing breeze to survive in the burning heat in regions with a hot and dry climate.

Over time, palm leaves were replaced by beautiful and exquisite fans made of expensive materials – peacock feathers, gold, precious stones, etc. The history of the fan over time is extremely interesting, which we will cover in a separate publication, but:

A truly revolutionary discovery was the invention of the electric fan!

The electric fan is a building block for many advanced technologies we use every day! Fans are needed to cool the heat generated by the processor and other components in computers, lasers, large LED lights, gasoline and electric cars, a space station, and countless other things. Fans used in HVAC systems allow people to build huge or underground buildings.

It is hard to imagine a world without electric fans!

Table of Contents

- What is an Electric Fan?

- 1734 – Frenchman John Theophilus Desagulier Invents the Pfan to Ventilate Mines

- 1882 – Schuyler Skaats Wheeler Invents the Electric Fan with Two Blades

- 1889 – Philip H. Diehl Patents the Ceiling Fan

- 1894 – Foundation of Heating and Air Conditioning Technology by German Professor Hermann Rietchel

- 1896 – Fans with More Than Two Blades are Produced. Fans Design Evolutes.

- 1904 – Philip H. Diehl Invents the First Oscillating Fan

- 1910 – Electric Fans are Used in Households

- 1920 – Electric Fans are Used in Commercial Buildings

- 1933 – Silver Swan Appears with a Radically Elegant Design

- 1940 – The Packard is the First Car to Offer Optional “Factory Air” in a Vehicle

What is an Electric Fan?

An electric fan is a machine powered by electricity to create a flow of air. It is made up of a spinning arrangement of vanes or blades that act on the air. They are usually constructed of wood, plastic, or metal.

The rotating unit of blades and hub is called an impeller, rotor, or runner. It is usually contained in some type of housing. This could help guide airflow or improve safety by avoiding things from colliding with the fan blades.

Most fans are powered by electric motors, but other power sources can be used, such as hydraulic motors, hand cranks, and internal combustion engines.

Actually, a fan can be any revolving vane or vanes used to create air currents from a mechanical standpoint. In contrast to compressors, which produce high pressures at a low volume, fans produce high volume and low pressure (but greater than ambient pressure) air flows. When exposed to an air-fluid stream, a fan blade will often rotate, and devices that take advantage of this, such as anemometers and wind turbines, often have fan-like designs.

The electric fan has blades that resemble a water or steam turbine. A DC or AC motor drives a rotating shaft. Over the years, fans have become much smaller and lighter. As the electric motor and blade design have improved, engineers have figured out how to get more power out of a design that uses less copper and steel.

1734 – Frenchman John Theophilus Desagulier Invents the Pfan to Ventilate Mines

John Theophilus Desaguliers FRS (March 12, 1683 – February 29, 1744) was a British natural philosopher, clergyman, engineer, and Freemason who was elected to the Royal Society in 1714 as an experimental assistant to Isaac Newton.

He had studied at Oxford and later popularized Newton’s theories and their practical applications in public lectures. Desaguliers’ most important patron was James Brydges, 1st Duke of Chandos.

As a Freemason, Desaguliers was instrumental in the success of the first Grand Lodge in London in the early 1720s, serving as its third Grand Master.

In addition to his interest in steam engines and hydraulic engineering (in 1721 he fixed a problem in the water supply of the city of Edinburgh), he developed expertise in ventilation. He developed a more powerful chimney, which was used in the House of Lords, and invented the fan wheel, which for many years extracted stale air from the House of Commons.

1882 – Schuyler Skaats Wheeler Invents the Electric Fan with Two Blades

Schuyler Skaats Wheeler (May 17, 1860 – April 20, 1923) was an American electrical engineer and manufacturer who invented the electric fan, an electric elevator, and the electric fire engine. He is associated with the early development of the electric motor industry, particularly the training of the blind in this industry for gainful employment.

He helped develop and implement a code of ethics for electrical engineers and was associated with the electrical industry in one way or another for over thirty years.

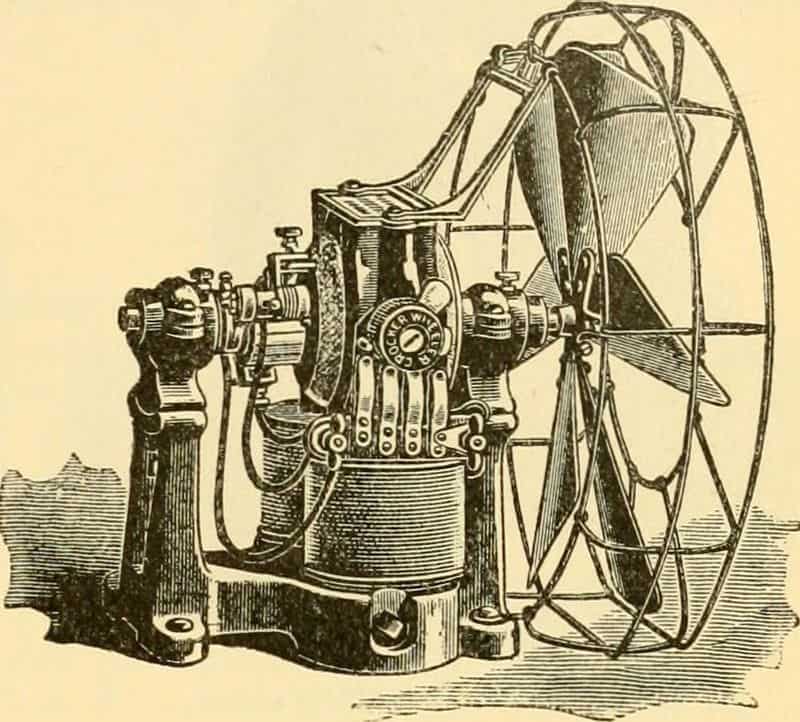

Schuyler Skaats Wheeler invented the fan in 1882 by placing a two-bladed propeller on the shaft of an electric motor. It was popularly called the “humming fan.” In 1904, the Franklin Institute awarded him the John Scott Medal for developing the “electric fire extinguishing system.”

Wheeler’s patent for the electric fire extinguishing system was filed on May 23, 1882. On February 24, 1885, the United States Patent Office officially recognized his patent for the “Electric Fan.”

In addition to inventing the fan, Schuyler Skaats Wheeler also invented the electric arc lamp in 1877. From 1883 to 1888, he was president of the Edison Electric Company. He then joined A.B. Dick, a manufacturer of electrical equipment, as a consultant. In 1890, Wheeler moved west and helped install electric lighting in San Francisco.

In addition, Wheeler invented an electric voting machine in 1907. This was done as part of the application process for membership in the Automobile Club of America at that time. Previously, the board had used an old-fashioned method of throwing a small colored ball into a ballot box to determine the applicant’s approval or disapproval.

The black-and-white ball plan of voting yes or no was fine as long as there were not many applicants for membership. Voting became very time-consuming when the list of applicants became very long. This was due to the mechanical handling of the small balls and the storage box for the ballots.

Wheeler invented a new technology that used electricity to provide instant voting and immediate results. He was the club’s first vice president and consulting engineer. His innovation was that each club member simply sat in his chair and pressed a button to cast his vote.

This transmitted the vote electrically to the central ballot box. Each voter had a small wooden block in his hand containing two push buttons, one black, the other white. If the member had no objection to the candidate being accepted as an official member, he or she pressed the white button.

The vote was then immediately registered in the central ballot box, which recorded all member votes electrically. If they felt the club would be better off without the applicant, the voting member pressed the black button for an immediate count. In both cases, these votes were tabulated secretly and securely, and the result was displayed immediately.

1889 – Philip H. Diehl Patents the Ceiling Fan

Philip H. Diehl (January 29, 1847 – April 7, 1913) was a German-American mechanical engineer and inventor who held several U.S. patents, including electric light bulbs, electric motors for sewing machines and other applications, and ceiling fans. Diehl was a contemporary of Thomas Edison, and his inventions caused Edison to lower the price of his light bulb.

A few years after Schuyler Skaats Wheeler’s invention of the ventilator in 1882, Philip Diehl mounted a fan blade on a sewing machine motor and attached it to the ceiling. In doing so, he invented the ceiling fan, for which he applied for a patent in August. The patent was granted on November 12, 1889.

He later added a lighting device to the ceiling fan. In 1904, Diehl and Co. added a ball joint that allowed the fan to be reversed; three years later, this developed into the first oscillating fan.

Besides this, in the basement of his home on Orchard Street in Elizabeth, New Jersey, Diehl invented a lamp that was different from Thomas Edison’s electric light bulb, patented in 1879. Diehl’s lamp had no lead wires.

In 1882, Diehl received the first patent for this induction incandescent lamp. The base of the lamp contained a coil of wire that connected to a primary coil in the lamp socket so that current flowed through the lamp without the need for lead wires. Two more patents were issued in 1883, followed by patents for electric lighting systems in 1885 and 1886.

Diehl erected the city’s first arc lamp in front of the Corey Building in Elizabeth, which still stands at 109 Broad Street.

Diehl’s work at Singer to improve the sewing machine led to the development of electric motors, first to power sewing machines and later for other purposes. In 1884, at the Franklin Institute in Philadelphia, Pennsylvania, he demonstrated a dynamo modeled on his smaller motor that produced a current for arc lamps, sewing machine motors, and incandescent lamps, all of which were covered by his patents. The legal committee of the exhibition judged it to be one of the best dynamos exhibited.

1894 – Foundation of Heating and Air Conditioning Technology by German Professor Hermann Rietchel

Hermann Immanuel Rietschel (April 19, 1847 in Dresden; February 18, 1914 in Charlottenburg ) is considered the founder of heating and air conditioning technology. He was a son of the sculptor Ernst Rietschel and brother of the theologian Georg Rietschel. The physician and general practitioner in Dresden Wolfgang Rietschel was his half-brother.

In 1894, German professor Hermann Rietchel published The Guide to Calculating and Designing Ventilation and Heating Installations. He is regarded as the founder of modern heating, air conditioning, and ventilation technology, which gained recognition as a new discipline in mechanical engineering through his work.

His four-volume guide to calculating and designing heating and ventilation systems is still regarded as the standard work in building technology. He also recognized the interaction between hygiene and technology for heating and ventilation and advocated a comprehensive approach to these topics.

Rietschel developed the idea of using the heat generated during the generation of energy (waste heat) as district heating for heating buildings and districts. He also developed the well-known ribbed radiator and provided the basis for its calculation.

He designed the heating and ventilation systems for the Reichstag building in Berlin, the theaters in Berlin, Munster, Ulm, and Strasbourg, the Hamburg City Hall, the Ministry of Justice in Tokyo, and the Federal Palace in Bern. Rietschel is regarded as one of the pioneers of modern mechanical engineering.

His other research interests include:

- Pipe network calculations

- Radiator tests

- Installation instructions for gas furnaces

- Steam heating

- Water heating

- District heating and district heating

- church heaters

- Economics of heating systems

- Ventilation systems

- Indoor climate

- Testing of heating fittings

- Testing of filter materials

- Hygienic requirements for heating systems

- Investigations of thermal insulation materials

1896 – Fans with More Than Two Blades are Produced. Fans Design Evolutes.

The electric fan was invented with two blades in 1882. 14 years later, the first fans with more blades appeared. Now most of the fans have 4 ot 5 blades to achieve an ideal balance between the amount of air circulated and ambient noise.

Early electric motors were bipolar. They were operated by direct current, with all parts exposed. The first blades were taken from the windmill and usually consisted of six pie-shaped, flat brass blades.

Speed control was by means of a resistor. In almost all cases, resistance wire was used, and in a few cases, the light bulb was used as a resistor. These early fans were either a novelty or an expensive device used in large offices or wealthy homes.

After Tesla’s work on AC motors, most manufacturers went to this standard. In the early 1890s, motors became enclosed. Fan cages began to appear. The purpose of the cage was not to protect the user, but rather to protect the expensive fan and blades from damage. Blade shapes remained six-bladed. The AC motor was controlled by induction rather than resistance.

Around 1900, blade designs began to change and competition increased. The first oscillating fans appeared on the market. Initially, they were wind-driven, and in 1904 the first mechanical oscillating fan appeared.

In 1906, the theory of the electric motor was completed. The only improvement in motor design occurred in the 1930s. The biggest improvement in motors was improved insulation of the copper wires used to wind the motors.

Until the early 1890s, these wires were wrapped in silk and later in cotton to insulate them. Improved enamel insulation allowed the use of smaller wires and thus, the production of smaller motors.

By 1910, most fan manufacturers were using rounded blades, if not patented designs themselves. All major manufacturers made some form of wind-driven or mechanical oscillator. The motors were now all enclosed and smaller.

1904 – Philip H. Diehl Invents the First Oscillating Fan

As mentioned above, in 1889, Philip H. Diehl patented the ceiling fan and later, he added a lighting device to it. In 1904, Diehl and Co. added a ball joint that allowed the fan to be reversed; three years later, this developed into the first oscillating fan.

1910 – Electric Fans are Used in Households

The decade of 1910-1920 brought great changes. Around 1910, electric fans were manufactured for home use. These “residential fans” were made for the bedroom. They had six blades and ran at a slower speed to be quieter.

Fans were still an important appliance. By 1912, manufacturers were able to “turn” brass housings for small fans. A short time later, they were also able to “turn” or stamp steel for motors and bases.

With the approach of World War I, there was a brass shortage as brass was needed for munitions. By the end of the decade, brass cages had been replaced by steel cages. All blades were now round in shape. Engines shrank from 8″ diameter to 5″. Almost all manufacturers used black as the color for the fan housings, but General Electric opted for a deep green.

1920 – Electric Fans are Used in Commercial Buildings

By 1920, cooled air was making its way into commercial buildings. Fan manufacturers began marketing fans more for residential use as the new cooling displaced their commercial markets. Manufacturers began experimenting with design changes.

Two competitors introduced fans in the shape of radio speakers with brown wood grain. Late in the decade, General Electric introduced overlapping blades, which operated much more quietly. These early blades were also made of aluminum rather than steel. Aluminum was now increasingly used in manufacturing.

1933 – Silver Swan Appears with a Radically Elegant Design

In early 1930, a young woman named Jane Evans came to St. Louis to work as an interior designer. She was introduced to the president of Emerson Electric. She proposed a radically elegant design. In 1932, Emerson introduced the Silver Swan.

The blade, made of aluminum and based on a yacht propeller design, was a great success and probably helped Emerson survive the Depression. More aluminum was used for the blades,, and the designs varied widely.

Many colors were offered, including ivory, forest green, dark brown, chrome, and nickel, and the motors received their last major change. Emerson introduced the capacitor start motor. These started faster, ran quieter, and were much more efficient.

The motors were now only 4″ in diameter and could drive a 16″ blade of cast aluminum. Cast aluminum blades came on the market, made to the latest aerospace industry designs. Some used nylon instead of brass or steel for the gears. Gray, aqua, and turquoise colors, as well as wrinkled paint finishes, were introduced.

1940 – The Packard is the First Car to Offer Optional “Factory Air” in a Vehicle

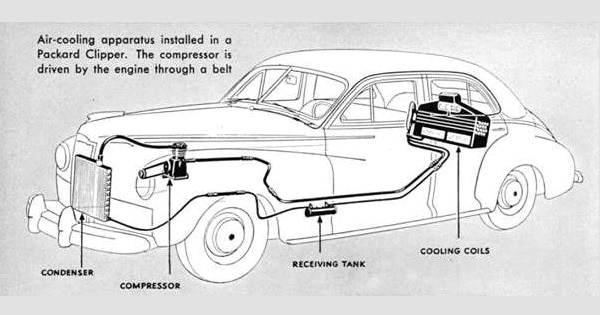

The 1940 Packard was the first car to have factory-installed air conditioning. By 1969, more than half of all new cars sold were equipped with air conditioning. Some brands placed window stickers to advertise their air-conditioned cars. For cars that did not have factory air conditioning, dealer-installed units under the dashboard became popular.

Actually, the 1940 Packard was not the first car with air conditioning. Popular workshop magazines of the 1930s contain numerous examples of homemade and experimental air conditioning systems in cars.

But Packard was the first to offer this feature as a regular production option. (The cost was $275 to $310). At that time, the term “air conditioner” had not yet caught on in the company. Packard first called its system “mechanical cooling” and later “weather conditioning.” (Note the ad at the bottom of this page.)

The Packard system, which was supplied by the Bishop & Babcock Mfg. Co. of Cleveland, was essentially similar to a modern air conditioner but had several key differences. First, the evaporator coil and blower were located behind the rear passenger seat, as shown above.

While this arrangement was far from ideal, as it took up a lot of trunk space and cooled the necks of passengers, it was common practice for air conditioning systems in automobiles until 1954, when both Nash and General Motors introduced dashboard-integrated systems similar to those of today.

A vertical two-cylinder compressor bolted to the cylinder head of the inline-8 engine and driven by a V-belt circulated DuPont Freon refrigerant. And if you take a second look at the pulley drive, you’ll discover something interesting.

Unlike modern air conditioners, there is no electromagnetic clutch and thus no way to shut off the compressor. For cold weather use, the drive belt had to be removed. Another shortcoming: there was no fresh air supply, and the stale interior air was endlessly recirculated. The Packard unit was a fully functional air conditioner, but it had a few problems that made it not quite suitable for the broad consumer market.

An unspecified number of Packards from 1940-42 were equipped with the groundbreaking air conditioner, and some of them survive today. The Bishop & Babcock unit was also fitted to some 1941 Cadillacs and Chrysler Imperials, and was also a paid option on the 1942 DeSoto.

So although air conditioning was technically available in American cars before the World War II, in practice it did not take hold in the market until the early 1950s. By 1970, nearly half of all new American cars sold were reportedly equipped with air conditioning, and today the figure is plus or minus 100 percent.

In the 1960s – Ceiling fans almost became obsolete due to the popularity of air conditioning. However, since the 60s, fans grew in popularity and became more energy efficient. In 1970s – Ceiling fans were well-used during the energy crisis because they consumed less energy than air conditioners.

Today, many years after the invention of the electric fan, they are widely used in the cooling systems of many devices we use every day. Even we personally use portable fans to survive the hot summer.